Produk

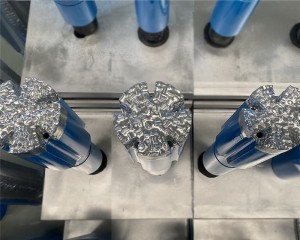

Efisiensi tinggi Downhole Milling Parabot

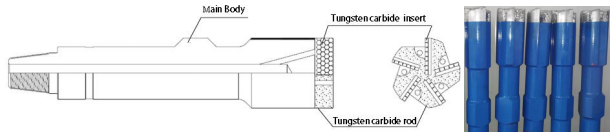

Bahan Produk

Candak sapatu pabrik datar handap sabagé conto:

Awak utama adopts-kinerja tinggi alloy steel (4145H) pikeun mastikeun operasi lemes jeung éféktif dina rupa tekanan pangeboran jeung kaayaan speed usaha Rotary. Samentara éta, urang ngadopsi tingkat tinggi tungsten carbide meterial pikeun ngahontal panggilingan gancang. Stabilizer sareng rok luar pikeun pabrik junk sareng pabrik taper tiasa dirarancang upami diperyogikeun.

Tungsten carbide sisipan

·Superloy

Pangisi anu hadé pikeun samangka, senar sareng pabrik taper.

Alus balik pikeun pabrik junk.

Rupa-rupa ukuran sadia.

Paling kasar.

· Métal Muncher

Mills leuwih gancang ti parabot panggilingan konvensional.

Ngurangan tekanan pangeboran diperlukeun bari panggilingan.

Nyéépkeun potongan anu langkung mulus tanpa biwir pikeun lebu ngagantung.

Ngahasilkeun lebu kalayan ukuran anu sami.

Motong logam tinimbang grinding eta.

· Opti-cut

Uing leutik.

ROP langkung gancang.

Panjang umur.

Turunkeun tekanan sareng syarat torsi.

16 titik motong sarta 8 motong edges pikeun tiap cutter.

Kategori produk

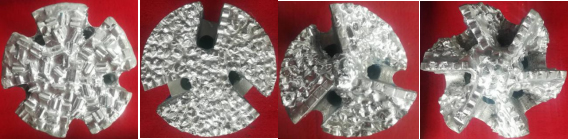

kerung / datar / agul Bottom ngagiling junk

Dipaké pikeun panggilingan bit, congcot, gauge diaméterna, grapple huntu, pipa nyeuseuh, alat pangeboran gabungan, asesoris pompa sumur jero, packer, distributor cai sarta parabot pangeboran panjang lianna.

Pabrik junk Petrozhr sayogi dina sababaraha konfigurasi sareng géométri. rékayasa ngagiling canggih kami sarta welder ngalaman mastikeun struktur motong konsisten tur awét dina unggal ngagiling junk.

Tab. 1 Datar / kerung / agul Bottom junk ngagiling parameter

| Borehole Dia. Ngagiling Shoe OD Disarankeun Panjang (mm) (mm) Thread Screw (mm) | PN Datar | PN Cekung | PN Bladed |

| 95.2- 101.6 89 2-3 / 8REG 250 | JM089FX | JM089CX | JM089BX |

| 107.9- 114.3 97 2-3/8REG 250 | JM097FX | JM097CX | JM097BX |

| 117.5- 127 110 2-7 / 8REG 250 | JM110FX | JM110CX | JM110BX |

| 130- 139.7 121 2-7 / 8REG 250 | JM121FX | JM121CX | JM121BX |

| 142.9- 152.4 130 2-7/8REG 250 | JM130FX | JM130CX | JM130BX |

| 155.6- 165. 1 140 3- 1/2REG 250 | JM140FX | JM140CX | JM140BX |

| 168- 187.3 156 3- 1/2REG 250 | JM156FX | JM156CX | JM156BX |

| 190.5-209.5 178 3- 1/2REG 250 | JM178FX | JM178CX | JM178BX |

| 212.7-241.3 200 4- 1/2REG 250 | JM200FX | JM200CX | JM200BX |

| 244.5-269.9 232 4- 1/2REG 250 | JM232FX | JM232CX | JM232BX |

| 273-295.3 257 6-5 / 8REG 250 | JM257FX | JM257CX | JM257BX |

| 298.5-317.5 279 6-5/8REG 250 | JM279FX | JM279CX | JM279BX |

| 320.6-346. 1 295 6-5/8REG 250 | JM295FX | JM295CX | JM295BX |

| 349.3-406.4 330 6-5/8REG 250 | JM330FX | JM330CX | JM330BX |

| 406.4-444.5 381 6-5/8REG 250 | JM381FX | JM381CX | JM381BX |

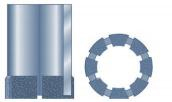

Sapatu Rotary

Sapatu Rotary ngadopsi bahan karbida di jero silinder pikeun motong circumferentially luhur lauk anu henteu teratur, sareng laun-laun ngalereskeun luhureun lauk anu ruksak kana bunderan, sapertos pipah, awak casing, jsb.

[Catetan: Kusabab diaméter huntu panggilingan jero tina sapatu rotart badag, torsi sabalikna badag, jadi tekanan lemah sareng mode rotasi slow kudu diadopsi dina pamakéan sapatu Rotary. Sacara umum, tekanan pangeboran teu kudu ngaleuwihan 10 KN jeung speed rotational teu kudu ngaleuwihan 50 r / mnt.]

Tipe A

Potong logam, semén sareng formasi.

Motong on OD na handap.

Tipe B

Motong logam dimana clearance leutik.

Motong dina ID na handap.

Tipe C

Wangunan motong.

Motong on OD na handap.

Tipe D

Cut formasi jeung lauk dina waktos anu sareng.

Motong dina ID, OD sareng handap.

Tab.2 Parameter sapatu Rotary

| Casing / Wellbore Dia. | Sapatu Rotary OD (mm) | Sapatu Rotary Panjangna (mm) | Disarankeun Screw Thread | PN Sapatu Rotary | |

| 4 di | 101,6 mm | 95 400 | FJWP | TXX095 | |

| 5- 1/2 di | 139,7 mm | 114 500 | FJWP | TXX114 | |

| 5-3 / 8 di | 146,05 mm | 118 500 | FJWP | TXX118 | |

| 6-5 / 8 di | 168,28 mm | 136 425 | FJWP | TXX135 | |

| 7 di | 177,8 mm | 152 450 | FJWP | TXX152 | |

| 7-5 / 8 di | 193,68 mm | 160 450 | FJWP | TXX160 | |

| 8-5 / 8 di | 219. 1 mm | 185 550 | FJWP | TXX185 | |

| 12- 1 / 4di 311. 15mm | 203 450 | FJWP | TXX203 | ||

| 15-5 / 8di 396,88mm | 298 450 | FJWP | TXX298 | ||

| 20 di | 508 mm | 406 450 | FJWP | TXX406 | |

Taper Mill

Ngagiling taper reams kaluar larangan, rubuh casing jeung liner bagian jeung deburr whipstock jandéla jeung casing.The low tungtung ngagiling taper, jeung leutik, diaméterna asup ka casing rubuh jeung liner.Then rada spiraled reamer edges ka ngagiling jauh di handapeun bagian ka pinuh. diaméterna gilinding .

Pabrik taper diwangun ku awak kerucut sareng karbida tungsten. The taper awak nyaéta 30 derajat, congcot ngawangun jangjang, sarta beungeutna hardfacing atanapi inlaying tungsten carbide.

Tab.3 Parameter ngagiling taper

| liang bor Dia. Taper ngagiling OD Disarankeun Panjangna (mm) (mm)sekrup Benang(mm) | P.N. Taper ngagiling | ||

| 95- 101.6 | 89 | 2-3 / 8REG 300 | XZ089 |

| 107.9- 114.3 97 2-3/8REG 300 | XZ097 | ||

| 117.5- 127.0 110 2-7/8REG 300 | XZ110 | ||

| 130- 139.7 121 2-7 / 8REG 300 | XZ121 | ||

| 142.9- 152.4 130 2-7/8REG 300 | XZ130 | ||

| 155.6- 165. 1 140 3- 1/2REG 300 | XZ140 | ||

| 168- 187.3 156 3- 1/2REG 300 | XZ156 | ||

| 190.5-209.5 178 3- 1/2REG 300 | XZ178 | ||

| 212.7-241.3 200 4- 1/2REG 300 | XZ200 | ||

| 244.5-269.9 232 6-5/8REG 350 | XZ232 | ||

| 273-295.3 257 6-5 / 8REG 350 | XZ257 | ||

| 298.5-317.5 279 6-5/8REG 350 | XZ279 | ||

| 320.6-346. 1 295 6-5/8REG 350 | XZ295 | ||

| 349.3-406.4 330 6-5/8REG 350 | XZ330 | ||

| 406.4-444.5 381 6-5/8REG 350 | XZ381 | ||

Samangka String Mill

Sapatu senar samangka mangrupikeun salah sahiji alat panggilingan dina operasi sidetracking. Hal ieu dianggo pikeun ngalereskeun casing, reaming sareng muka saluran. Biasana dianggo langsung saatos muka windows. Ujung panggilingan (wilayah kerja) tina pabrik samangka ngahubungi témbok borehole, sareng tungtung unggal ujung dirancang salaku congcot. Nalika jandela dibuka, pabrik samangka tiasa manjangkeun jandela ti luhur sareng ngaleungitkeun skala sareng burrs anu tinggaleun dina témbok pipa nalika motong awal.

Tab.4 Samangka string ngagiling parameter

| Borehole Dia. Screw (mm/in) Thread | Wewengkon Gawé OD (mm/in) | Panjang Wewengkon Gawé (mm/in) | Panjang Totul (mm/in) | PN |

| 139,7 (5- 1/2) NC 26 112 (4-7/ 16) 600 (23-5/8) | 1130 (44) | XGMX112 | ||

| 139,7 (5- 1/2) NC 26 116 (4-9/ 16) 600 (23-5/8) | 1130 (44) | XGMX116 | ||

| 139,7 (5- 1/2) NC 26 118 (4-5/8) 600 (23-5/8) | 1130 (44) | XGMX118 | ||

| 139,7 (5- 1/2) NC 31 120 (4-3/4) 600 (23-5/8) | 1280 (50) | XGMX120 | ||

| 146,0 (5-3/4) NC 31 124 (4-7/8) 600 (23-5/8) | 1280 (50) | XGMX124 | ||

| 168,3 (6-5/8) NC 31 142 (5-9/ 16) 600 (23-5/8) | 1280 (50) | XGMX142 | ||

| 177,8 (7) NC 31 151 (5- 15/ 16) 600 (23-5/8) | 1280 (50) | XGMX151 | ||

Pilot gilinding

Pilot ngagiling dirancang pikeun panggilingan casing, liner, sapatu usaha Rotary atanapi tubing ID badag. Bilah motong diasah ku bahan tungsten carbide kelas tinggi nyieun ngagiling pilot Petrozhr bisa ngahontal penetrasi gancang kalayan wear.The minimal lebu motong na curled gampang dipiceun. Jeung tungtung pilot dipaké pikeun nyaimbangkeun dina ID obyék nu keur giling.

Tab.5 Parameter gilinding pilot

| liang bor Dia. (mm) | sekrup Benang | Wewengkon Gawé OD (mm) | Panjang bilah motong (mm) | Pilot Area Panjang (mm) | PN |

| 153 2 3/8REG | 130 200 | ≧45 | LYMX130 | ||

| 165 2 3/8REG | 140 200 | ≧45 | LYMX140 | ||

| 187 3 1/2REG | 156 200 | ≧55 | LYMX156 | ||

| 210 4 1/2REG | 178 200 | ≧55 | LYMX178 | ||

| 241 4 1/2REG | 200 200 | ≧55 | LYMX200 | ||

| 270 4 1/2REG | 232 200 | ≧55 | LYMX232 | ||

| 295 6 5/8REG | 257 250 | ≧55 | LYMX257 | ||

| 317 6 5/8REG | 279 250 | ≧55 | LYMX279 | ||

| 346 6 5/8REG | 295 300 | ≧55 | LYMX295 | ||

| 406 6 5/8REG | 330 300 | ≧55 | LYMX330 | ||

| 445 6 5/8REG | 331 300 | ≧55 | LYMX331 | ||

Bagan aplikasi Tungsten carbide

| Aplikasi anu disarankeun | Superloy | Opti-cut | Metal-muncher | Metal-muncher kalawan Superloy |

| Washover liang muka | √ | √ | ||

| Pipa bor washover | √ | |||

| Washover gravel pak | √ | √ | ||

| Washover liner motong | √ | |||

| Packer washover | √ | |||

| Poilt panggilingan | √ | |||

| Ngagiling junk leupas | √ | √ | ||

| packer stasioner atawa pipa atawa tubingjunk panggilingan | √ | |||

| Ngagiling samangka | √ | |||

| Panggilingan string | √ |

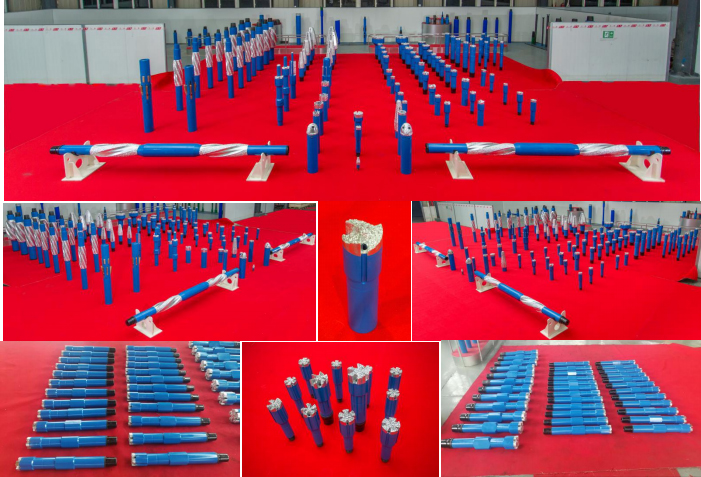

Fishing Item Gambar

Room 703 Gedong B, Greenland puseur, Hi-tech zone ngembangkeun Xi'an, Cina

Room 703 Gedong B, Greenland puseur, Hi-tech zone ngembangkeun Xi'an, Cina 86-13609153141

86-13609153141